Facilities Efforts Restore ISEC to Energy Efficiency Potential

The Interdisciplinary Science and Engineering Complex (ISEC) is an iconic building on Northeastern’s Boston campus that was built with sustainability in mind, achieving LEED Gold certification. ISEC’s state-of-the-art mechanical systems are designed to reduce energy demand and capture and reuse waste heat. This complex system needs to have all components working in concert to achieve these benefits, and after the first year, the building’s energy data showed that it was underperforming. Using advanced modeling and data from the building, the Facilities team was able to optimize ISEC’s energy systems and get the building to meet its designed energy efficiency targets. As Northeastern moves towards more advanced and energy-efficient systems for all its buildings, this optimization process was an important learning process that will inform how we approach and implement our projects in the future.

Sustainable Design

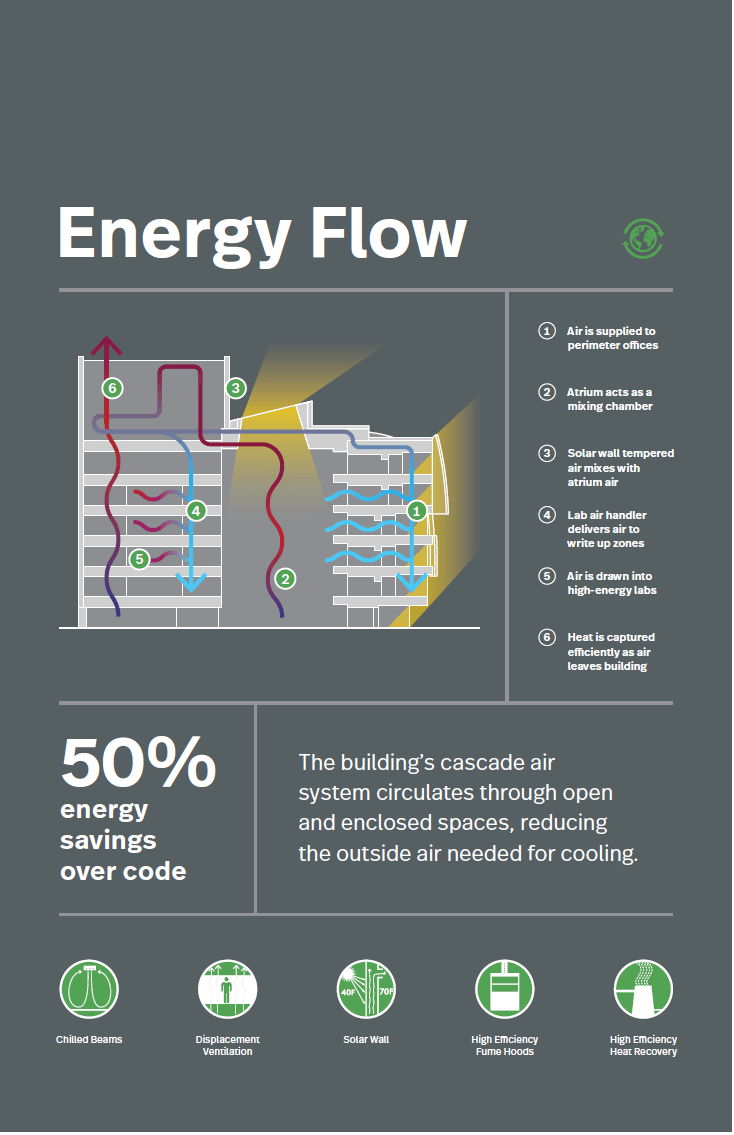

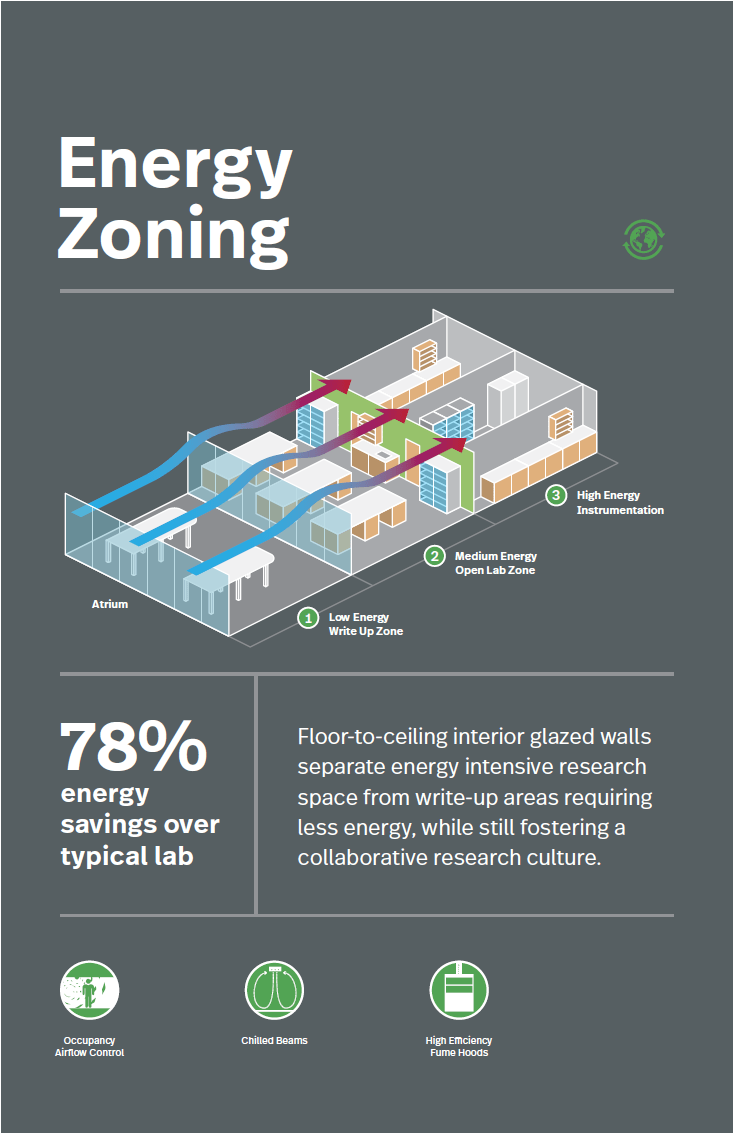

ISEC was designed as a cutting-edge research facility supporting the study of molecular and tissue engineering labs, human-centered robotics, and brain and cognitive health research, as well as many other disciplines. This research requires a large amount of energy, but ISEC was designed to achieve energy savings of 50% from a typical research building.

ISEC sustainability features start on the outside with brown panels that encircle the triple-glazed glass exterior. The panels are designed to achieve a 78% reduction in peak solar heat gain, reducing the demand on the air conditioning systems on hot summer days, but also maximize sunlight during the winter.

Inside, highly efficient, state-of-the-art mechanical systems limit the need for fossil fuel consumption through heat recovery, reducing need for outside air with a cascade air system, and lots of natural light from the atrium.

When Joe Ranahan, the Director of Energy at Northeastern, saw the plans and sustainability goals for the project, he was impressed.

“I couldn’t believe the numbers in the energy model,” Ranahan said. “The current stock of research buildings on campus do not use the same modern technology that ISEC does and typically consume 3-4 times the energy per square foot that ISEC was projected to use.”

From Design to Operation

But there was a year-long learning curve. The Facilities team had to learn how to operate the building, as well as identify where the performance issues were. When the building had been operating for about a year, the Facilities teams recognized that their efforts to fix the building could not be achieved through small changes. A collaborative team was formed to work through each issue and in 2022, the building finally reached its energy performance potential through the dedicated work of the NU Facilities team.

The team worked with a host of internal and external experts to evaluate the building’s energy usage and operation. Among all the opportunities for improvement identified, the following items were the key sections that required adjustments for the building to operate efficiently:

- Heat Recovery Chiller

- Chilled Beams

- Chiller Condenser Pump

- Lighting systems software

Heat Recovery Chiller

The biggest effect on system operations was getting the heat recovery chiller to work optimally. The heat recovery chiller, where heat is recovered from the operation of the chiller to cool the building, is designed as the primary source of heat and cooling for ISEC. While there are backup systems to ensure there is enough heating and cooling capacity during the warmest and coldest days, the heat recovered by chilled water production for cooling creates enough heat to be captured as the primary source of heat for ISEC, especially during the “shoulder” seasons between winter and summer when there is a higher demand for both cooling and heating simultaneously.

The heat recovery chiller as installed in ISEC did not have the proper software configuration to allow the system to run correctly. This failure resulted in the less efficient backup heating and cooling systems being used as the primary systems. A resolution was finally achieved when an expert from the manufacturer of the systems was able to travel to campus to diagnose and repair the complex software and system configuration to be able to correctly communicate with the rest of the building systems.

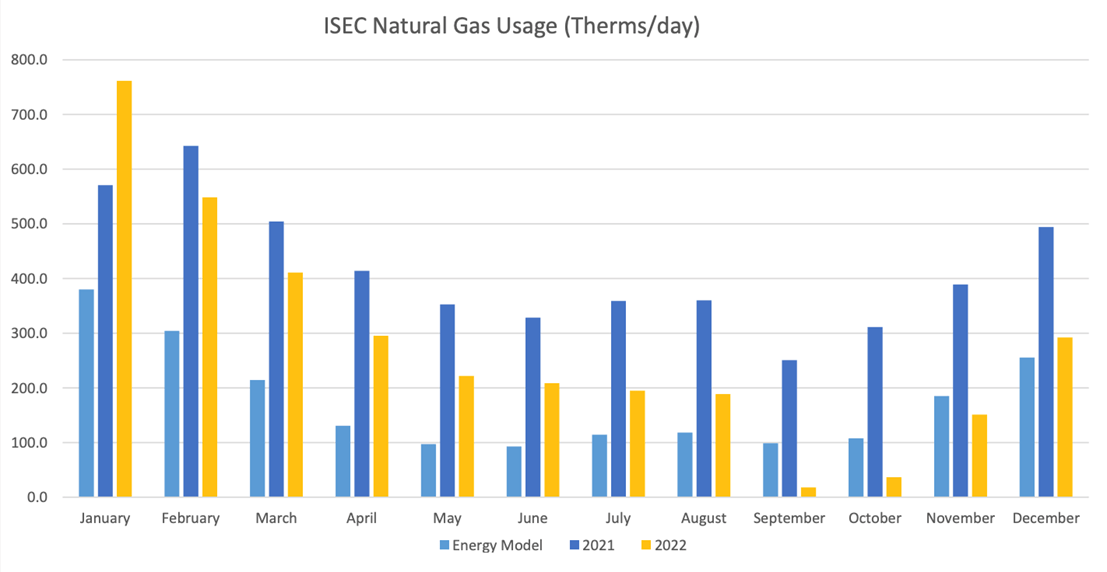

As seen in the chart below, energy savings are significant starting in October 2022, with the improved operation of the heat-recovery chiller providing a huge reduction in natural gas use.

Chilled Beams

Chilled beams provide heating and cooling to the majority of labs and offices in ISEC by using chilled water or hot water to deliver heat and cooling to spaces in the building instead of forced air. Water is a more efficient way to move heating and cooling which makes chilled beams a very efficient way to condition a space.

As installed, the chilled beam systems had flow constricted which caused some spaces to overheat and need to use more inefficient systems to provide the cooling. The restriction was the result of a design error and needed to have piping and valves changed to solve the problem.

Chiller Condenser Pump

The pump was running at full capacity 24-7 pumping water up seven stories even without need for the extra cooling. This was likely caused by previous efforts to fix other systems in the building incrementally, demonstrating the intricacy and connectedness of building automation systems and the importance of identifying proper systems balance to achieve the desired outcomes.

Future Operations

Ultimately, the changes made and lessons learned have been extremely valuable in the design and construction of Northeastern’s newest science and engineering building, EXP, which will open within the next year and use many of the same energy systems as ISEC.

“It was a great learning experience for everybody and ISEC is truly a sustainable building now,” Ranahan said. “Much more energy efficient than I would ever have believed at the beginning of the design process for the amount of research that is in that building. I look forward to applying these learnings to our all future building projects”